The forklift is one of the most commonly used pieces of equipment on the worksite. These powered industrial trucks are used to lift and transport loads with deft and precision. Although forklifts are powerful, there is risk involved in operating any industrial machine. With over an estimated one million forklifts estimated to be in operation, it’s essential to ensure crews are trained on proper forklift safety measures.

The Occupational Health and Safety Administration (OSHA) estimates that forklift accidents cause roughly 34,900 serious injuries and 85 fatal accidents every year. Even more alarming is that 25 percent of these accidents result from inadequate training, showing the importance of educating every worker on the critical rules of safe forklift operation.

By brushing up on forklift training, you and your team can rest easy knowing that construction site safety is a priority. Use the links below to navigate to important information about forklift safety.

- OSHA Forklift Safety Rules

- Forklift Safety Tips

- What Are the Main Causes of Forklift Accidents?

- Forklift Pedestrian Safety

- How Can I Improve My Forklift Safety?

1. Get Forklift Certification

Since many accidents are due to poor forklift safety training, it is recommended that only those who are trained and licensed in accordance with OSHA standards be responsible for operating a forklift. Employers should evaluate their employees’ performance at least once every three years and supplement training with forklift safety videos, lectures, software training and demonstrations.

2. Wear Proper Clothing

Forklift operators should be dressed with the appropriate safety equipment, including safety shoes, hard-hats and a high-visibility jacket. Make sure to tuck away loose clothing to prevent it from getting caught on the forklift.

3. Know the Forklift Class

OSHA recognizes many different forklift types and classifications. Since each type has its own structure, weight limit, traveling speed, turning radius and usage, it’s important to know your equipment in order to follow the best safety practices.

4. Inspect the Equipment Daily

You should thoroughly inspect forklifts before every use. Daily checks with the shift supervisor are recommended to identify and log any problems or defects. Any equipment that requires repair should never be operated.

These checks do not need to be lengthy or complex. Here’s a quick forklift safety checklist that construction sites can implement based on OSHA’s recommendations.

- Test operating controls such as brakes, lights, horn and steering wheel.

- Check mast and overhead guard for damage.

- Examine tire and fluid levels (hydraulic, brake, engine, fuel and coolant).

- Check for water, oil or radiator leaks.

- Ensure the forks are in good condition (e.g. straight, no cracks, no distortion).

- Look for potential hazards.

When using a forklift, following all worksite rules, signs and regulations is of upmost importance. Here are some best practices to help you observe your operating environment and protect yourself and the other individuals on the worksite.

5. Maintain 360° Visibility

Keep forks low to the ground to provide clear forward visibility. If the load restricts your visibility, operate the equipment in reverse. Always ensure you have a good view of the rack when you are positioning the load. Additional best practices defined by OSHA are:

- Always make eye contact with pedestrians and other workers

- Always look in the direction of travel

- Use rear-view mirrors to boost visibility

- Use headlights if working at night, outdoors, or in areas where additional lighting is needed

You can read the rest of the tips on the OSHA website.

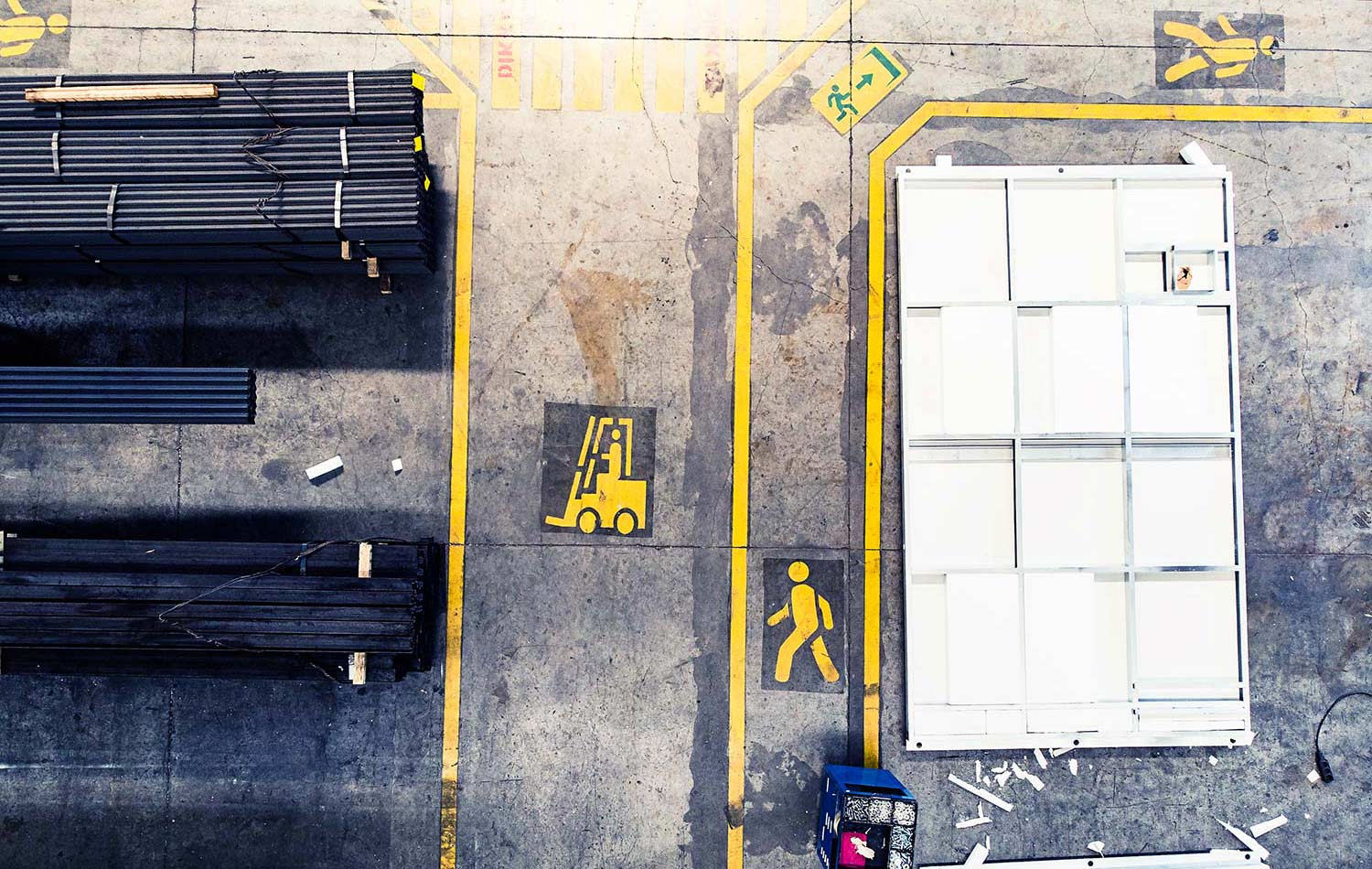

6. Implement a Floor Marking System

A floor marking system can help increase worker safety. Use yellow to mark physical hazards, such as areas prone to falling or stumbling, and red to delineate fire hazards, fire equipment and emergency switches. Place wayfinders and signs throughout the site to keep pedestrians away from forklift paths, lead forklifts along safe routes, and improve the overall flow of traffic.

7. Maintain Equipment Capacity

Be aware of the capacity of your forklift and any attachments used. Avoid hauling weight that exceeds the counterweight of the forklift. Because of the way forklifts work, overloading can cause the rear wheels to rise off the ground and can make the whole machine fall over. This can cause injury to personnel and damage to the equipment and materials.

8. Never Carry Extra People

Do not allow other workers to ride on the equipment with you unless a second seat is fitted into the forklift. Do no use the forklift to lift people, as forklifts are designed to carry loads. If you need to lift a person, use only a secure work platform and a forklift safety cage.

9. Pay Attention to the Forklift’s Stability

Before using a forklift, make sure your hands and shoes are completely dry and sit in a comfortable position with all the controls within reach. In addition to seating yourself securely, take the following steps before operating the forklift to increase your safety.

Each forklift has a center of gravity – the point where the weight has equal concentration – that it shares with the load it carries. Forklifts are built on a three-point suspension system, called the “stability triangle” that operators must stay within to prevent it from tipping over. The heavier the load, the further out the center of gravity is from the load center, decreasing your forklift’s lifting capacity.

10. Ensure Loads are Stable and Secure

When placing loads on the loading dock, be sure to check them for balance. Travel with the load tilted backward and keep forks as low as possible to increase the stability of the equipment, especially when navigating on ramps. Use ropes or bindings to secure stacks and heavy loads if necessary and make sure any pallets or skids used are the appropriate weight for the load.

11. Move at the Appropriate Speed

Drive your forklift within the designated speed limits. It’s important to not stop, turn, change directions suddenly, or move fast when making sharp turns, as these actions can cause the forklift to tip over. If your forklift starts to dip, do not try to jump clear of the machine. Experts recommend staying in the vehicle, gripping the wheel, and bracing your feet.

12. Maintain a Safe Operating Distance

Always be mindful of the surrounding equipment on the worksite. Do not operate a forklift in close proximity to other machinery unless absolutely necessary, and keep a safe distance to allow you room to stop safely and avoid other machines that are moving in an unpredictable manner.

13. Avoid Hazardous Areas of the Equipment

Avoid standing or walking under a load, lifting mechanism, or forklift attachment, as loads can fall off on anyone positioned below it. Keep hands and feet clear away from the forklift mast, as a moving mast can cause serious injury.

14. Refuel and Recharge the Forklift

It’s important to keep equipment fully charged and fueled. Be sure to recharge and refuel in specially designated locations, which are usually well-ventilated and flame-free areas. Be diligent in switching off the equipment every time it’s being refueled.

15. Park the Forklift at the End of the Shift

At the end of the shift, be sure to always park the equipment in the designated and authorized areas. The construction company should make sure the parking areas do not block pathways or obstruct any exits or entrances. Fully lower the forks until they fit the floor, apply the parking brake, turn off the engine, and remove the key from the ignition.

What Are the Main Causes of Forklift Accidents?

The main causes of forklift accidents fall into three risk categories: user error, work environment, and mechanical design. Inadequately trained personnel are responsible for a significant portion of forklift accidents. OSHA estimates that as many as 70 percent of forklift accidents could have been avoided through proper training.

Here are the primary causes of major fatal forklift accidents according to the Industrial Truck Association.

Overturned vehicles are the leading cause of forklift fatalities. There are a number of factors that contribute to forklift tip-overs, including user errors like improper turning, driving with elevated loads, and turning or stopping too quickly as well as environmental factors like unstable surfaces and unclear forklift lanes.

Forklift Pedestrian Safety

Since almost 80% of forklift accidents involve pedestrians, it’s vital to keep pedestrian safety in mind when operating forklifts. The best strategy is to train both operators and pedestrians on proper safety procedures.

Operator Reminders

- Always yield to pedestrians.

- Sound the forklift’s horn at blind corners and when backing up.

- Have a spotter assist in blind areas.

- Hand signal to pedestrians to stand clear or warn pedestrians of potential hazards before operating the forklift.

Pedestrian Reminders

- Remember forklifts cannot stop suddenly.

- Stand clear of areas where forklifts are in use.

- Be aware of the wide rear swing radius.

- Use pedestrian walkways.

- Never ride a forklift without authorization and the proper equipment.

- Never walk under a lifted load.

If operating a forklift in public where it’s not possible to train pedestrians, forklift operators should exhibit extra caution.

How Can I Improve My Forklift Safety?

Buying or renting a forklift that is safe and from a trusted supplier is a great place to start, but the lift operator is the most important component of safe forklift practice. Safety training helps protect operators from injury and death, liabilities, OSHA fines for non-compliance, loss of resources, high insurance premiums, high maintenance costs and property and product damage. In one study, OSHA found that proper training of forklift operators may reduce the accident rate by up to 30 percent.

To become a qualified forklift operator, you’ll want to obtain a forklift certification from a training program that is compliant with OSHA policies.

In addition to training, construction companies can ensure personnel safety by providing proper maintenance on forklifts, maintaining a clear and obstacle-free workplace environment and boosting employee morale through a strong safety culture. Addressing these issues can help prevent forklift accidents and improve safety practices in the workplace.