When you need to lift and move heavy loads, you might use a crane. While there are many types of cranes — including mobile cranes, fixed cranes, and even floating cranes — they all have features in common. Most cranes have a main mast or boom, a hoist system, and some sort of outrigger or counterweight to prevent the crane from tipping over.

Although crane accidents have decreased since 1992 thanks to OSHA regulations, they still happen and can result in injuries or death. The most common type of fatal crane injury occurs when someone is struck by an object or equipment. Proper training is essential to reduce accidents on the jobsite.

This article covers common crane-related accidents, injury statistics, and safety tips.

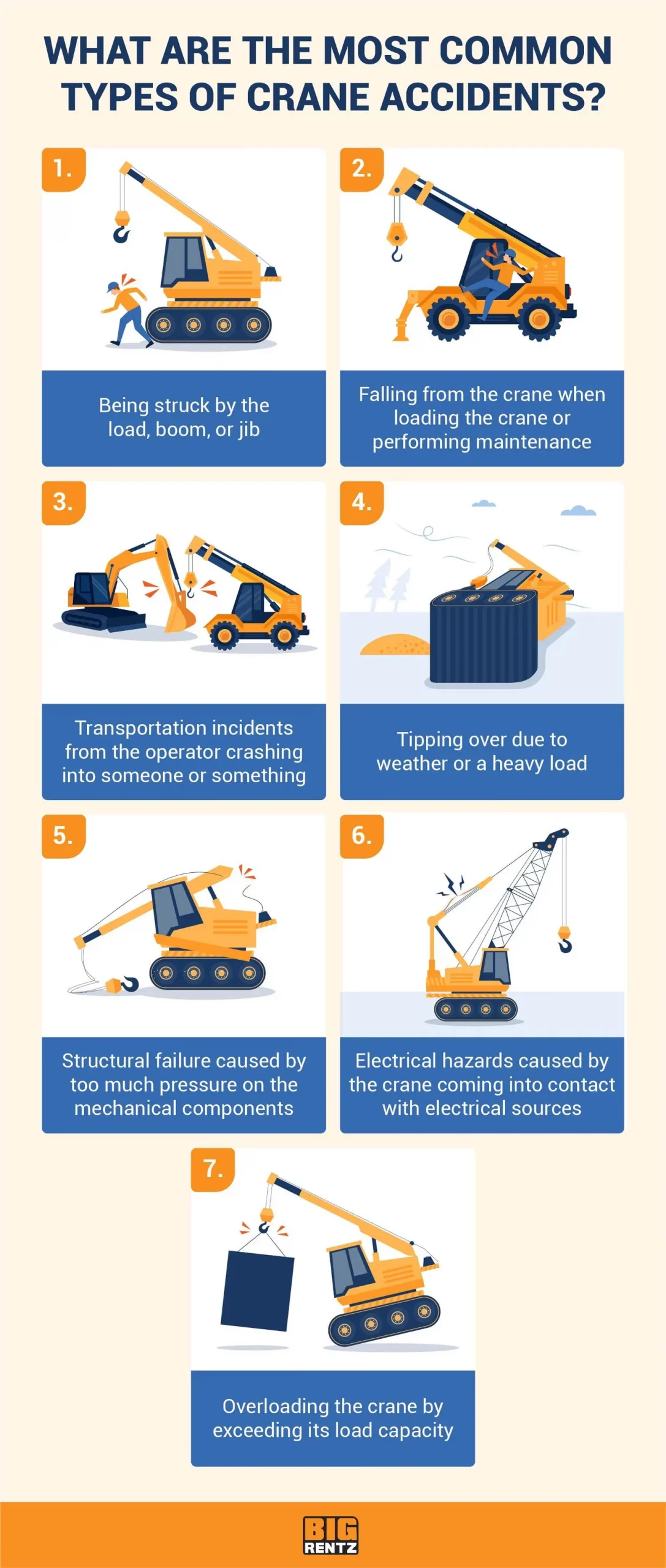

The Most Common Types of Crane Accidents

The most common cause of crane injuries are ones where workers are hit by an object or equipment. According to the U.S. Bureau of Labor Statistics, 154 crane fatalities occurred between 2011 and 2017 after employees were struck by an object or the crane.

| Causes of Fatal Crane-Related Injuries | Total Fatal Crane-Related Injuries Between 2011–2017 |

| Struck by an object or the equipment | 154 |

| Falls to a lower level | 41 |

| Transportation incidents | 39 |

Being Struck by the Load, Boom, or Jib

Serious injuries may occur when a worker is hit by the load, the crane boom, or jib.

Causes

This accident involves someone being struck by an object falling from the crane, or the crane itself, such as a moving boom. This could happen if the load comes loose or there aren’t sufficient measures to keep workers out of the lift zone.

Prevention

Safe crane operation begins with rigging the load properly to prevent materials from shifting. You may also want to start the day by reviewing the work ahead and steps that you can take to prevent injuries.

When operating a crane, listen for alarms and horns, obey signs and spotter signals, and use designated travel routes.

On the worksite, even if you’re not operating a crane, you can take steps toward accident prevention. Avoid walking near large equipment when possible, and stick to the right path so you don’t stray into open traffic lanes. Be sure to make yourself visible by not standing in the shadows where visibility is low.

Falling From the Crane

Crane accident injuries sometimes result from workers falling from the crane.

Causes

Employees may fall from a crane to a lower level. For instance, someone can fall from a hoister crane while performing maintenance. Similarly, a worker may fall off an overhead crane when trying to unload steel plates.

Prevention

Fall protection systems should be put in place to keep crane operators and maintenance providers safe. For example, a fall arrest system, which consists of a harness and lanyard, will catch you if you fall off the crane platform.

Additionally, operators should maintain three points of contact with the cab when entering and exiting. Remember to wear the proper personal protective equipment (PPE) to help prevent injury.

Transportation Incidents

Another common cause of crane accidents includes transportation incidents.

Causes

A vehicle may collide with a crane or the crane operator may run the machine into a structure, person, vehicle, piece of equipment, or other obstacle.

Prevention

Maintaining communication with a spotter is essential. Spotters are the operator’s eyes on the ground, using crane hand signals and radio commands to guide the load. In addition to using a spotter, the operator should take steps to ensure their vision isn’t obstructed and make sure the area is clear before operation begins.

Tipping Over

Although cranes include built-in safety features to increase stability, they still sometimes tip over.

Causes

Cranes can tip due to being overloaded or improperly using outriggers, the hydraulic posts that stabilize the machine. External factors such as high wind or uneven ground can also cause the crane to tip over.

Prevention

To prevent tipovers, it’s essential to follow the load chart for weight capacity in the crane cabin manual. Before beginning a task that requires outriggers or stabilizers, the operator must verify that they are positioned in accordance with the crane manufacturer’s recommendations.

In windy weather, check the crane’s maximum wind speed to make sure that it can lift the load safely. Finally, ensure that the ground is level or that you are using a rough-terrain crane, which is typically equipped with four large rubber tires and four-wheel drive.

Structural Failure

Sometimes crane accidents occur when crane parts fail or the crane itself collapses.

Causes

Cranes can collapse when too much pressure is put on the structural components. This can cause the machine to fall on anyone in the lift area below the crane. Like tipovers, collapses can result from loads that exceed specified weight limits. Accidents can also be caused by individual crane parts failing, such as hoist lines breaking, booms cracking, or hydraulic systems failing.

Prevention

To avoid crane collapses, tipovers, and structural failure of components, you need to follow the manufacturer’s guidance on capacity limits. Also, make sure to conduct regular inspections and perform scheduled maintenance to ensure structural components are in good shape and not worn down or defective.

Electrical Hazards

Electrocution from power sources may cause dangerous and even fatal occupational injuries. For that reason, when operating cranes near overhead power lines, employers must take preventative measures, per OSHA regulations.

Causes

If a crane or its load comes into contact with power lines or other electrical sources, a current can flow through the crane, its load, or the ground and shock or electrocute the crane operator or other workers near the crane.

Prevention

The lift director in charge of overseeing crane operators should ensure that power lines near the crane operating site are de-energized. OSHA guidelines also dictate that you should assume that any overhead power line you encounter is energized. The only reason not to make this assumption is if you know it has been de-energized, per indications by the owner or utility company, and you can see that it is visibly grounded.

OSHA requirements indicate that you can prevent making physical contact with power lines by using independent insulated barriers. Managing your clearance between the crane, including its load, and energized power lines is important as well. Use visual means or another person to help you keep a minimum clearance.

Crane Accident Statistics

Crane fatality statistics show us that operating heavy equipment can be dangerous when done improperly.

- In 2017, there were 33 crane-related fatalities, the lowest number since 1992. In 1992, there were 116 crane-related fatalities, most of which occurred when someone was struck by an object or piece of equipment.

- Between 2011 and 2017, 43% of crane-related fatalities were in the construction industry and 24% were in the manufacturing industry.

- Between 2011 and 2017, Texas had the most crane-related fatalities with 50. Florida and New York had the next highest number, with 16 each, and California and Illinois had 14 each.

| U.S. State | Total Fatal Crane-Related Injuries Between 2011–2017 |

| Texas | 50 |

| Florida | 16 |

| New York | 16 |

| California | 14 |

| Illinois | 14 |

Crane Safety Guidelines

To avoid accidents on construction sites and other jobsites, follow the crane safety tips below.

- Choose the right crane for the job. Crane safety begins with selecting the correct crane for the task at hand. You may opt for a fixed tower crane for tall buildings like skyscrapers or a rough-terrain mobile crane for working in challenging off-road areas.

- Follow OSHA guidelines. Designed specifically to protect workers, OSHA regulations require that only trained and certified individuals operate cranes. Make sure to adhere to all applicable OSHA guidelines, including qualification of personnel, PPE, and adequate clearance.

- Read the operator manual. While reading the operator manual and maintaining regular equipment checks helps to ensure you know how to use the crane and keep it in good working order, follow these safety tips below to avoid accidents on construction sites:

-

- Maintain regular maintenance and equipment checks. Performing daily inspection checks and regular equipment maintenance can keep your machine functioning smoothly and alert you to potential problems.

- Clear obstructions before operating the machine. Prior to moving your crane, make sure you have a clear travel path and can stay clear of fixed objects like power lines. In addition, make use of a qualified signal person to lead the crane during travel.

- Stabilize the crane correctly. Many crane accidents stem from improper outrigger setup, so it’s important to follow manufacturer guidelines on proper stabilization. Do not place outriggers over voids, depressions, or unstable ground surfaces.

- Rig the load properly. To prevent loads from shifting or falling (and potentially causing injury), make sure to follow proper procedures when attaching the load to the crane.

- Keep the load within capacity. Although many modern cranes contain load sensors, crane operators should still understand how to read load charts to avoid overloading.

- Use common hand signals for communicating. Safe crane operation makes use of standard hand signals and communication protocols. A qualified signal person will use hand signs to tell the crane operator when to move the boom, when to lift and lower the load, and when to stop.

- Closely monitor difficult lifts. Complex lifts involving loads above 80 percent of crane capacity (50 percent on barges) present the highest risk for tip-overs or equipment failure. For that reason, these difficult lifts require a comprehensive safety plan and constant monitoring during the lift.

OSHA Crane Regulations

Employers must fulfill OSHA’s crane standard to ensure that the employees they oversee aren’t exposed to crane hazards. OSHA standards also explicitly establish certain tasks for some parties, including the following:

- Controlling contractors are responsible for ensuring that ground conditions are sufficient for the assembly of cranes or other covered equipment (see §1926.1402(c)).

- Utility owners/operators must provide voltage information for work occurring near power lines in certain circumstances under §§1926.1407-1409.

- Crane inspector duties are listed in §1926.1412. Shift and monthly inspections must be conducted by a competent person as defined in §1926.1401.

- The employer must ensure that each signal person meets the qualifications contained in §1926.1428. The standard outlines the duties of a signal person in §§1926.1419-1422.

- Until operator certification goes into effect, under §1926.1427 the employer must ensure that the crane operator is qualified under §1926.1427(k)(2).

Rent a Crane for Your Next Job

Both human error and equipment failure can result in crane accidents, but following the proper training requirements and safety protocols can help prevent them. If you’re looking to rent a crane for your next project, check out BigRentz. We have well-maintained modern cranes and other construction equipment that can help you get the job done when you need it.