If you’re in need of a forklift for your next construction job, you’re probably familiar with the many types of tires available on the market. Choosing the right forklift tires is very important—some types of tires work better indoors, while others are better for outdoor applications. You want to be sure the tire you choose supports the work you’re doing.

One type of tire you may have run into is the pneumatic tire. In this guide, we explain what pneumatic tires are, what types of tires are out there, and the pros and cons of using them.

What Is a Pneumatic Tire?

Pneumatic tires are rubber tires, commonly found on a variety of vehicles, from hand trucks and wheelbarrows to forklifts and tractors. They’re popular because of their strong rubber treads and excellent shock absorption, which help stabilize the vehicle and reduce bumps and jolts felt by the passengers or operators inside.

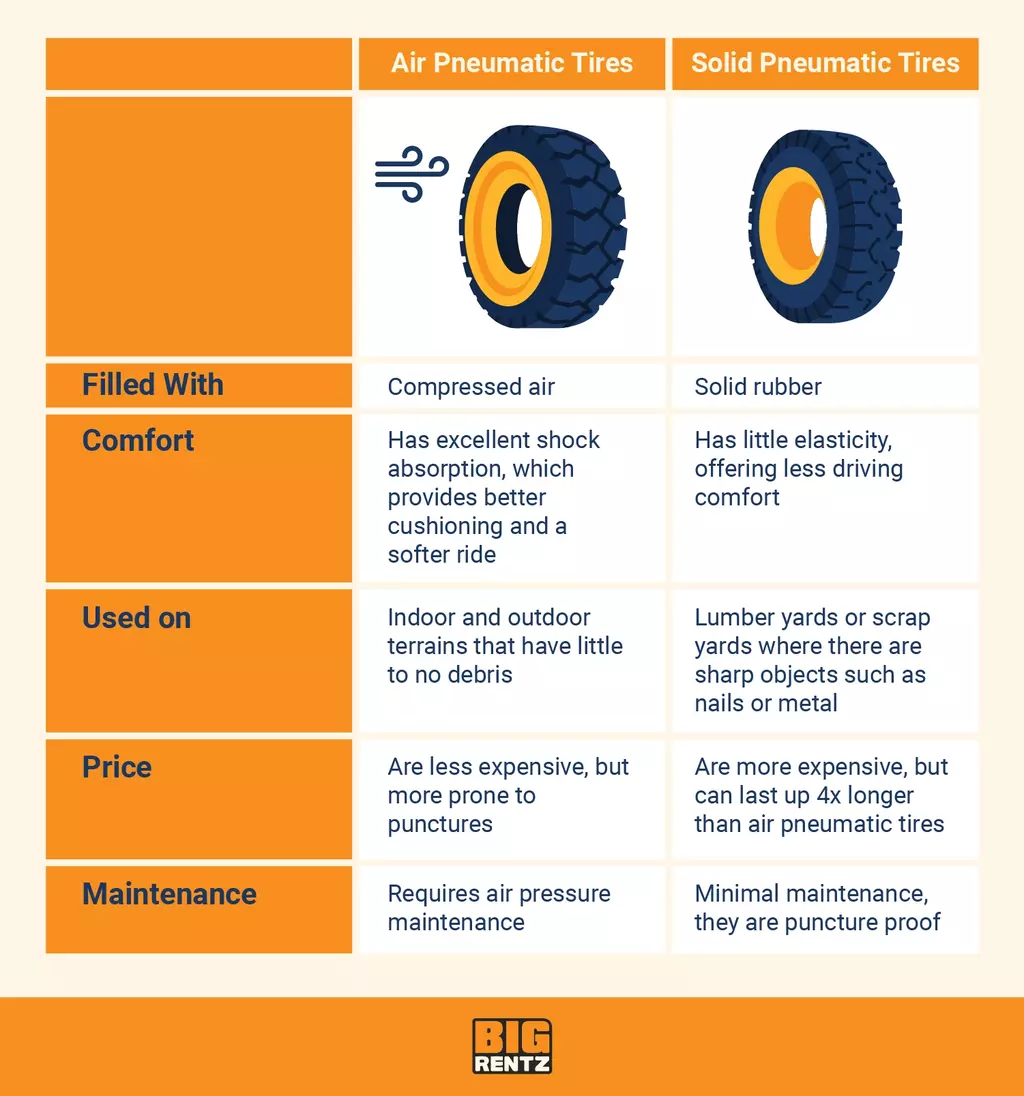

Forklift tires come in two types:

- Pneumatic tire: Filled with compressed air

- Cushion tire: Made out of solid, heavy duty rubber or filled with foam

Pneumatic Tires

Pneumatic tires are one of the most popular types of tires. They’re hollow, inflated using pressurized air, which gives them structure and traction. These air-filled tires are also relatively inexpensive, making them cost-effective for a construction project.

The fact that they’re air-filled, however, means they aren’t ideal for certain environments. Since air pneumatics are prone to puncture and wear and tend to bounce, they’re better to use on flat, even terrain, or for indoor jobs where the area is free of sharp objects.

Pneumatic tires are useful in off-road and outdoor applications, especially dealing with bumpy or uneven terrain where there are sharp objects, offering a smoother ride and somewhat more control for the operator.

Cushion Tires

Cushion tires, also called resilient or flat-free tires, are, as the name suggests, completely solid, made out of thick, heavy duty rubber, making them virtually puncture proof. While these solid rubber tires are more expensive, they tend to last much longer than pneumatic tires because they’re less prone to wear and puncture, and you don’t have to keep replacement tires on hand.

Foam-Filled Tires

Foam-filled pneumatic tires are somewhere in between these two. Basically, foam-filled pneumatics allow you to turn pneumatic tires into solid cushion tires by filling your tires with a liquid that hardens inside. They’re OTR, or off-road, pneumatic tires, often used as truck tires, or other large, weight-bearing vehicles.

Because they’re in between air tires and solid rubber tires, they can be useful in off-road and outdoor applications but are more prone to bounce and wear than heavy duty solid rubber tires.

Cushion Tires vs. Pneumatic Tires

Cushion tires, also called press-on tires, are made of smooth, solid rubber, fitted around a metal band. They’re inexpensive and easy to maintain, but they don’t get the same level of traction as pneumatic tires do. Cushion tires are designed to use on concrete or asphalt surfaces, which makes them more ideal for indoor environments like warehouses. Capable of a smaller turning radius, cushion tires work better in smaller spaces.

Pneumatic tires, on the other hand, because of their superior traction, are designed for both indoor and outdoor use. While cushion tires perform well in environments with indoor, flat conditions, like a warehouse, generally, pneumatic tires are better on rough surfaces than cushion tires, due to their rubber treads and larger frames.

Pros of Pneumatic Tires

If you’re looking for new tires, or the right type of tire for your forklift, here are some reasons to consider pneumatic tires:

- Durability: Pneumatic tires tend to be more durable than other types of tires due to their make, especially when they’re solid rubber tires.

- Noise reduction: Their soft rubber treads and superior shock absorption make pneumatic tires much quieter in action.

- Better traction: Not only does their traction allow pneumatic tires to take on uneven terrain, but it also makes them more versatile, useful for indoor, on-pavement, and off-road, outdoor applications.

- Shock absorption: Their shock absorption makes them safer to use on jobsites where workers may encounter bumps or when the loads your forklift carries need protection from sudden shocks.

Cons of Pneumatic tires

While they have many benefits, pneumatic tires may not be the ideal choice for every job. If these factors affect your job, you may want to consider a different type of tire:

- Less maneuverability: Because pneumatic tires are generally heavy, especially the solid rubber tires, they require significant push force to move. Their large design also makes it more difficult to make turns.

- Weight capacity: The higher the weight you need to bear, the heavier and bigger your tire size needs to be.

- Air pressure maintenance: For air-filled tires, the air pressure has to be closely monitored. If it drops too much, the tire won’t be as movable or effective.

- Puncture: Air-filled tires are also prone to puncture, especially on uneven terrain or around sharp objects.

Should You Consider Pneumatic Tires?

If you’re using a forklift outdoors, pneumatic tires should be at the top of your list for what types of tires to consider. They’re durable, provide great traction and shock absorption, and work on a variety of terrain. However, above all, you should carefully consider what type of tire is going to be best for you.

BigRentz can help match you with the right pneumatic tire forklift.