Scrapers, also called wheel tractor scrapers, are commonly used to scrape and level surfaces. These heavy-duty earthmoving machines can also haul earth and materials, such as dirt and gravel, more than just a short distance—they can move it from one job site to another.

Scrapers offer extreme efficiency over other earthmoving vehicles when it comes to transporting materials. Their all-in-on productive approach can be measured by their cycle times—the time it takes to load, haul, dump, and get back into position, and a single scraper operator can move up to 72 cubic yards of material per cycle, which can cut your labor in half.

Explore All Earthmoving Equipment

How Do Wheel Tractor Scrapers Work?

A scraper can be self-propelled or towed. In either case, it uses a scraping blade to cut into the earth and push the material into a bowl or a hopper.

Key Parts of a Wheel Tractor Scraper

- Scraper: The scraping blade dislodges material from the ground as the heavy machinery moves forward.

- Bowl: The bowl has a cutting edge that cuts the earth and then loads and carries it.

- Apron: This vertical blade, adjacent to the scraping blade, closes when the bowl is full, so the load is ready to be transported to a new location.

- Ejector: The ejector, at the rear of the bowl, uses hydraulics to expel loaded material.

How Are Wheel Tractor Scrapers Used?

Scrapers are known for their versatility. They can be used in the construction industry, agricultural operations, or mining jobs.

Wheel tractor scrapers can perform tasks and projects that include:

- Leveling

- Grading

- Excavating

- Road building

- Forestry applications

- Earthmoving

Types of Scrapers

Scrapers come in two general types: self-propelled scrapers (motor scrapers) and towed scrapers, which require a separate piece of construction equipment to haul them.

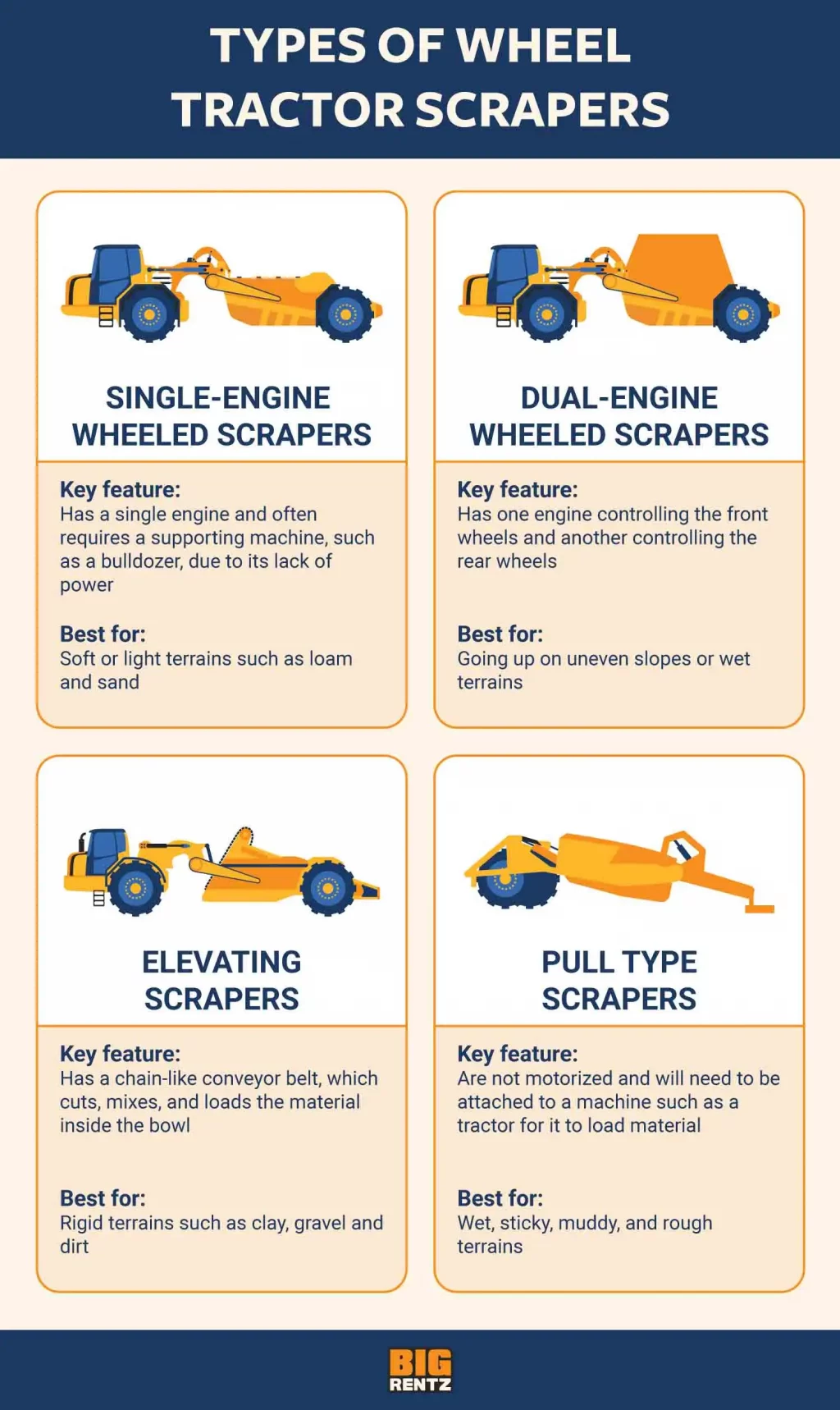

Single-Engine Wheeled Scrapers

Most often, a single-engine scraper lacks the power or traction to scrape material into its bowl on its own. It needs a bulldozer or tractor to help it load material by pushing it along. The dozer creates extra power to push against the weight of the dirt or other scraped material on top, as well as the force of gravity. A dozer can help scrapers take shortcuts, especially on inclines.

Dual-Engine Wheeled Scrapers

Duel-engine wheeled scrapers are able to load and pull the load themselves, which makes them ideal for rougher terrain. These scrapers are four-wheel-drive vehicles that have two engines, giving them extra power capacity. They’re also heavier, helping them gain better traction as they move. This two-engine configuration uses a self-loading push-pull system: One engine pushes as the other pulls, each helping the other to load.

Elevating Scrapers

Elevating scrapers use a chain-like conveyor belt that works like a paddlewheel. A hydraulic motor turns the chain. As this occurs, paddles attached to the chain push dirt upward into the bowl.

Unlike other types of scrapers, which come with an ejector, elevating scrapers use a retractable floor to release dirt from the bottom of the machine. Elevated scrapers work with minimal spillage and are well-suited for both hard and soft materials.

Pull Type Scrapers

Pull scrapers are unpowered trailers that must be attached to a tractor and pulled in order to load. Early scrapers such as the Fresno scraper fell into this category; they were typically pulled by horses. Because they lack a motor, pull scrapers are best used for lighter terrain such as sand, soil, or soft materials.

Pull scrapers come in two types. Carrier scrapers, which work better for wet and sticky material, use a hydraulic ejector or “pushoff wall” to unload, while dump scrapers utilize a hydraulic cylinder to pivot or turn the bowl over so it can dump its contents. This process works well for loose, dry soil.

Should I Use an Excavator or Wheel Tractor Scraper?

Both earthmoving machines are used for digging and excel at moving soft soils. The wheel tractor scraper can replace other equipment like a bulldozer or grader since it can scrape, load, grade, and haul earth all in one machine. An articulated truck and excavator, by contrast, can work better on wet clay or rocky soils where scrapers can’t operate as easily.

Do You Need A License To Operate A Scraper?

If you plan to rent a wheel tractor scraper, keep in mind that OSHA doesn’t provide certification, but requires all heavy equipment operators to be trained and capable of safely operating the machine. Depending on your location, you may have to register to operate a scraper. These registration requirements may vary from one state to the next.

If you need to rent any earthmoving heavy equipment, BigRentz has many types of earthmoving equipment available. You can choose from backhoes, articulated wheel loaders, trenchers, excavators, skid steer loaders, dozers, and more. Prices vary depending on what machine you choose and whether you rent it by day, week, or month.