When you conduct regular crane inspections, you can identify potential hazards and proactively perform preventative maintenance. OSHA has two classifications for crane inspections: frequent and periodic. Frequent inspections occur at daily, weekly, or monthly intervals, testing the crane for function and proper operation, while periodic inspections can occur bimonthly, quarterly, or yearly.

In this post, we go over the basics of crane inspection, including relevant OSHA standards, different types of inspections, and general inspection requirements.

Table of Contents

- OSHA Crane Inspection Requirements

- Who Should Inspect the Crane?

- When Must Crane Inspections Take Place?

- How to Conduct a Crane Safety Inspection

- OSHA Inspection Requirements for Idle Cranes

- Crane Safety Tips

- Do You Need a License to Operate a Crane?

OSHA Crane Inspection Requirements

OSHA standard 1926.1412 establishes crane inspection requirements. Here’s an overview of what’s required for a crane inspection.

The crane must be inspected by a “competent individual”

If you’re an employer, OSHA (1926.550) requires you to designate a competent person as the crane inspector. You must select a person familiar with crane components and capable of identifying potential hazards. They also must be authorized to take measures to eliminate those hazards, if any are found.

You must perform a functional test of the equipment

To prevent any potential problems or injuries that could occur while using the machine, cranes must be inspected before use, including initial use.

A functional test evaluates how the crane works and if it’s operating normally. The person you select to perform the inspection must look at and test all critical crane components, including the control system, braking system, power plant, and load-sustaining structural components like the hoisting equipment.

You must perform “frequent” and “periodic” inspections

Depending on how much and how often your crane is in use, you have to perform frequent and periodic inspections at appropriate intervals. OSHA Standard 1910.179 classifies frequent inspections as occurring daily to monthly, and periodic inspections as occurring at 1 to 12 month intervals.

Cranes in normal service to heavy service usually undergo visual inspections daily or weekly with annual inspections to test global structure integrity, while cranes in severe service need to be inspected both ways more frequently.

Who Should Inspect the Crane?

According to OSHA, crane inspections must be performed by a competent individual who is capable of identifying hazards and authorized to take corrective measures for them. A crane inspector can be a qualified employee appointed by the employer or come from a third-party company.

In addition to testing a crane for function, an inspector is responsible for identifying any maladjustments, defective parts, or deformations before the crane is used.

When Must Crane Inspections Take Place?

Frequent inspections must be done at daily to monthly intervals. They cover day-to-day operating mechanisms, making sure parts like the hydraulic system and hooks and hoist chains are working properly.

Periodic inspections happen bimonthly, quarterly, or annually depending on the crane’s activity. They look at overall wear, examining parts like the sheaves, rivets, sprockets, and brakes.

In addition to frequent and periodic inspections, initial inspections must be done on new or altered cranes. You must conduct comprehensive inspections at a minimum of every four years after the initial one for all new, altered, or used cranes.

Annual inspections must be conducted on or before the anniversary date of the last annual inspection.

How to Conduct a Crane Safety Inspection

Both frequent and periodic crane inspections follow set inspection checklists. Here’s an overview of what each type of inspection looks for. These standards apply to overhead cranes and gantry cranes as well.

Initial Inspection

Under OSHA Standard 1910.179, an initial crane inspection must be done prior to first use. The main difference between this type of inspection and a frequent or periodic inspection is that it’s performed before the initial use of the crane. This means that any issues should be reviewed and damaged parts should be replaced before the machine is ever operated. The basic crane functions should be tested and a load test should be performed.

Whether you’re dealing with a new crane, an altered crane, or a used crane, the procedures of an initial inspection are repeated every four years after the very first inspection.

Frequent Inspection

Frequent inspections can occur at daily to monthly intervals. They include inspections for defects or issues during operation hours and between regularly scheduled inspections.

Here’s a general checklist for daily crane inspections. The crane inspector must check:

- All functional operating mechanisms to make sure there’s no maladjustment that could interfere with proper operation or excessive wear of any components

- All parts of air and hydraulic systems, like lines, tanks, valves, and drain pumps, for deterioration or leakage

- Hooks for deformation or cracks

- Hoist chains, including end connections, for excessive wear, twist, distorted links, or stretch beyond manufacturer’s recommendations

- Rope reeving to make sure it complies with manufacturer’s recommendations

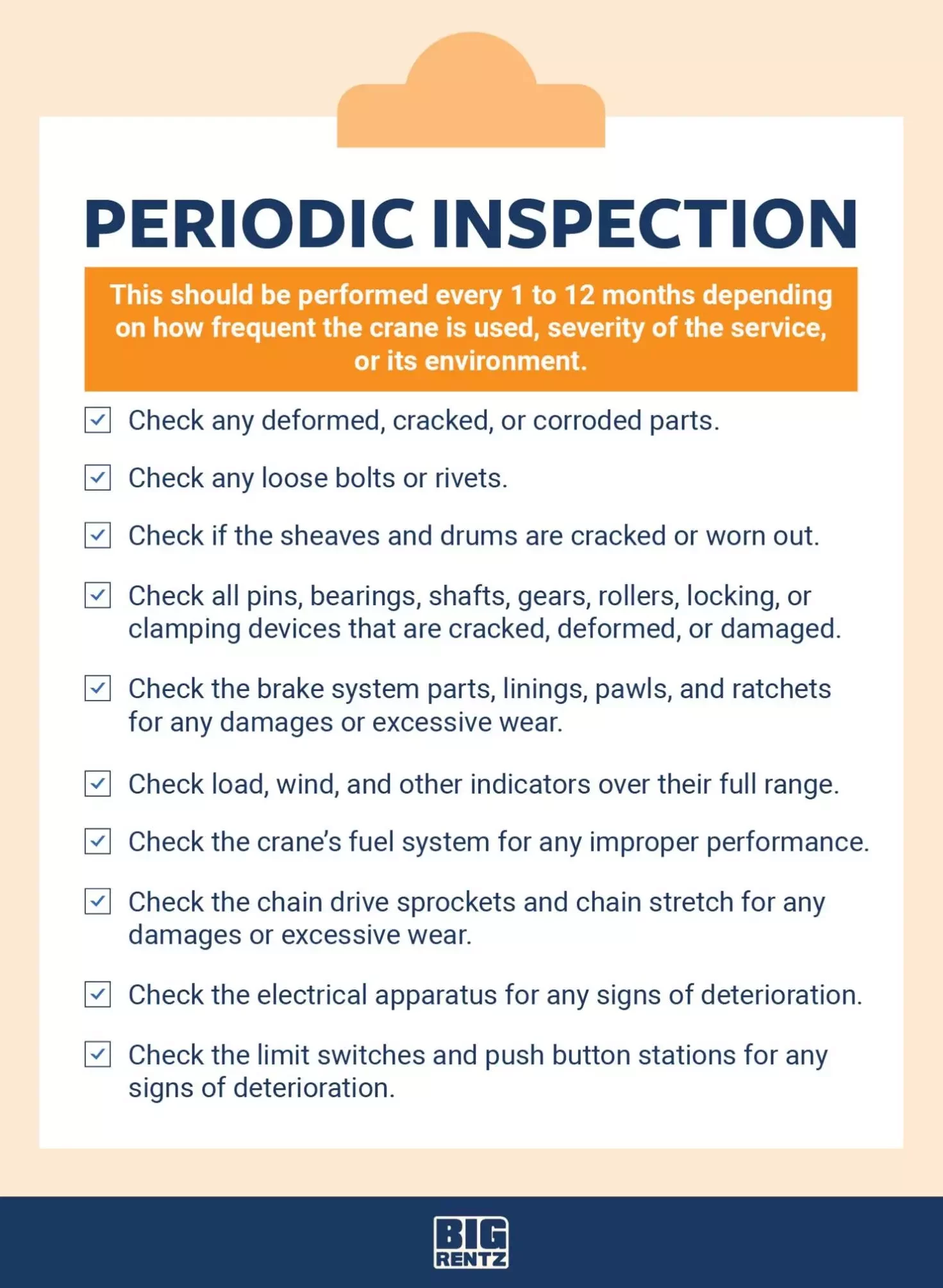

Periodic Inspection

Periodic inspections can occur bimonthly, quarterly, or annually depending on the crane’s activity, severity of service, and work environment. Here’s a general overview for periodic inspections. The crane inspector must check for:

- Deformed, cracked, or corroded members

- Loose bolts or rivets

- Cracked or worn sheaves and drums

- Worn, cracked or distorted components, like pins, bearings, shafts, gears, rollers, and locking and clamping devices

- Excessive wear on brake system parts, linings, pawls, and ratchets

- Load, wind, and other indicators over their full range, to catch significant inaccuracies

- Excessive wear of chain drive sprockets and excessive chain stretch

- Improper performance in gasoline, diesel, electric, or other power plants for noncompliance with applicable safety requirements

- Pitting or any deterioration of electric apparatus parts like controller contactors, limit switches, and push-button stations

OSHA Inspection Requirements for Idle Cranes

If a crane has been idle for one month or more, but less than six months, inspectors should follow the frequent inspection procedure when they inspect the crane.

If a crane has been idle for six months or longer, it should undergo a complete inspection. This entails going through the procedures of both a frequent inspection and a periodic inspection.

Crane Safety Tips

As with any piece of heavy-duty equipment, a lot can go wrong when a crane is used improperly. Here are some basic crane safety tips to help keep your team safe around a crane.

- Select the right type of crane. Make sure the crane is appropriate for the tasks you want to perform with it. Some cranes are mobile and some are fixed. Within these different types, you’ll find different load capacities and other capabilities, so you need to know your tasks’ details so you can choose the right equipment for your job.

- Read your crane operator manual. The manual gives you an accurate sense of your crane’s capabilities and limitations. You can get an idea of the layout of the controls and your specific model functions.

- Understand your crane’s load limits. Overloading your crane can cause hazards like tipping or deformation. Make sure you only load your crane to its designated capacity.

- Be aware of your jobsite environment and surroundings. When operating a crane, keep an eye on people, structures, and obstructions around you. Operate the crane on designated paths and use a spotter to alert you of any hazards.

Do You Need a License to Operate a Crane?

Yes, according to OSHA, crane operators must be certified, and you have to pass both written and practical tests. While the written test evaluates your knowledge of the machine, the practical test ensures you can operate it properly. A practical test generally assesses:

- Evaluating the crane per OSHA standards

- Operating and maneuvering the crane

- Applying load chart information

- Using safe shutdown and other securing procedures

If a crane operator needs to be recertified, OSHA requires a valid assessment of the operator’s performance. This usually involves completing a requisite number of work hours without any incident, along with a written and practical test.

Rent a Crane Today

If you’re looking for a crane to rent, you’ve come to the right place. Whether you’re in need of a mobile crane, carry deck crane, or another machine, BigRentz has all your equipment rental needs covered.

![Crane Inspection Requirements [With Checklists]](https://acropolis-wp-content-uploads.s3.us-west-1.amazonaws.com/construction-workers-inspecting-crane.webp)