The average weight of a forklift is about 9,000 lbs, about three times the weight of an average automobile. Forklifts typically require a counterweight to balance out the heavy loads carried on the fork. This counterweight averages 3,000 to 5,000 lbs.

To better understand how to manage your loads and follow your machine’s load capacity, this post offers information on the difference between forklift weight and capacity, calculating load capacity, and managing your loads effectively.

Forklift Weights by Machine

A forklift can weigh anywhere from 3,000 lbs for an electric forklift to 20,000 lbs for an eight-point lift truck. The forklift’s weight is also known as its service weight, which is the total of the vehicle, battery, and all its attachments.

You can find your forklift’s weight in your service manual. Heavier models will generally be able to lift heavier loads, with models classified as standard, mid, and high capacity. For instance, a Toyota electric forklift weighing just under 5,000 pounds can lift 3,000 or 3,500 pounds, while a Toyota High Capacity IC Pneumatic weighing more than 84,600 pounds can carry a 55,000-pound load.

The following table highlights the weights of some of the most popular forklift models on the market.

Standard Capacity Forklift Weights

| Forklift (Model) | Weight (lbs) | Capacity (lbs) |

| Toyota Core Electric Forklift (8FBC15U) | 4,930 | 3,000 |

| Toyota 3-Wheel Electric Forklift (8FBE18U) | 4,990 | 3,500 |

| CAT Electric Forklift (EP16ACN) | 6,900 | 3,500 |

| Toyota 8FGCU25 | 8,000 | 5,000 |

| CAT C5000 | 8,100 | 5,000 |

| Komatsu BX50 FG25ST-16 | 8,180 | 5,000 |

| Hyster H50FT | 8,924 | 5,000 |

| Yale GLC050 | 9,016 | 4,800 |

Mid Capacity Forklift Weights

| Forklift (Model) | Weight (lbs) | Capacity (lbs) |

| Toyota Core IC Cushion Forklift (8FGCU32) | 9,700 | 6,500 |

| Mitsubishi IC Cushion Tire Forklift (FGC35K) | 11,550 | 7,000 |

| CAT Compact LPG Forklift (GP35N) | 10,200 | 7,700 |

| Toyota Mid IC Pneumatic Forklift (8FD35U) | 12,820 | 8,000 |

High Capacity Forklift Weights

| Forklift (Model) | Weight (lbs) | Capacity (lbs) |

| CAT Diesel Forklift (DP60-100N3) | 28,462 | 22,000 |

| Hyster Heavy Duty Forklift (H550XD48) | 81,551 | 55,100 |

| Toyota High Capacity IC Pneumatic (THD-5000-48) | 84,620 | 55,000 |

Forklift Weight vs. Forklift Capacity

The actual weight of the forklift is not the same as its lift capacity, or load capacity, which is how much your forklift can carry. Heavier models can usually carry greater loads. Knowing your forklift’s capacity can keep you from overloading it and risking tipping or other forklift accidents.

How to Determine Forklift Weight

Your forklift’s service manual or manufacturer’s data plate will typically include its weight. As a general rule, if you don’t have your service manual handy or don’t know your forklift’s weight, you can estimate it by multiplying its lift capacity by either 1.5 or 2. The weight will likely be between these two figures.

How to Estimate Forklift Capacity

To operate your forklift safely, you’ll need to know how to calculate its load capacity. The Occupational Health and Safety Administration (OSHA) provides a formula for doing this if your actual load center is different from its rated load center, which is found on the machine’s data plate.

Using this formula, first divide the rated load center found on the data plate by the actual load center, and then multiply the result by the capacity of the forklift. So, if you had a lift with an actual load center of 48 inches and a rated center of 24 inches, you would divide 24 by 48 to get .5, then multiply this by its lift capacity — say 5,000 pounds — to get its safe capacity or 2,500.

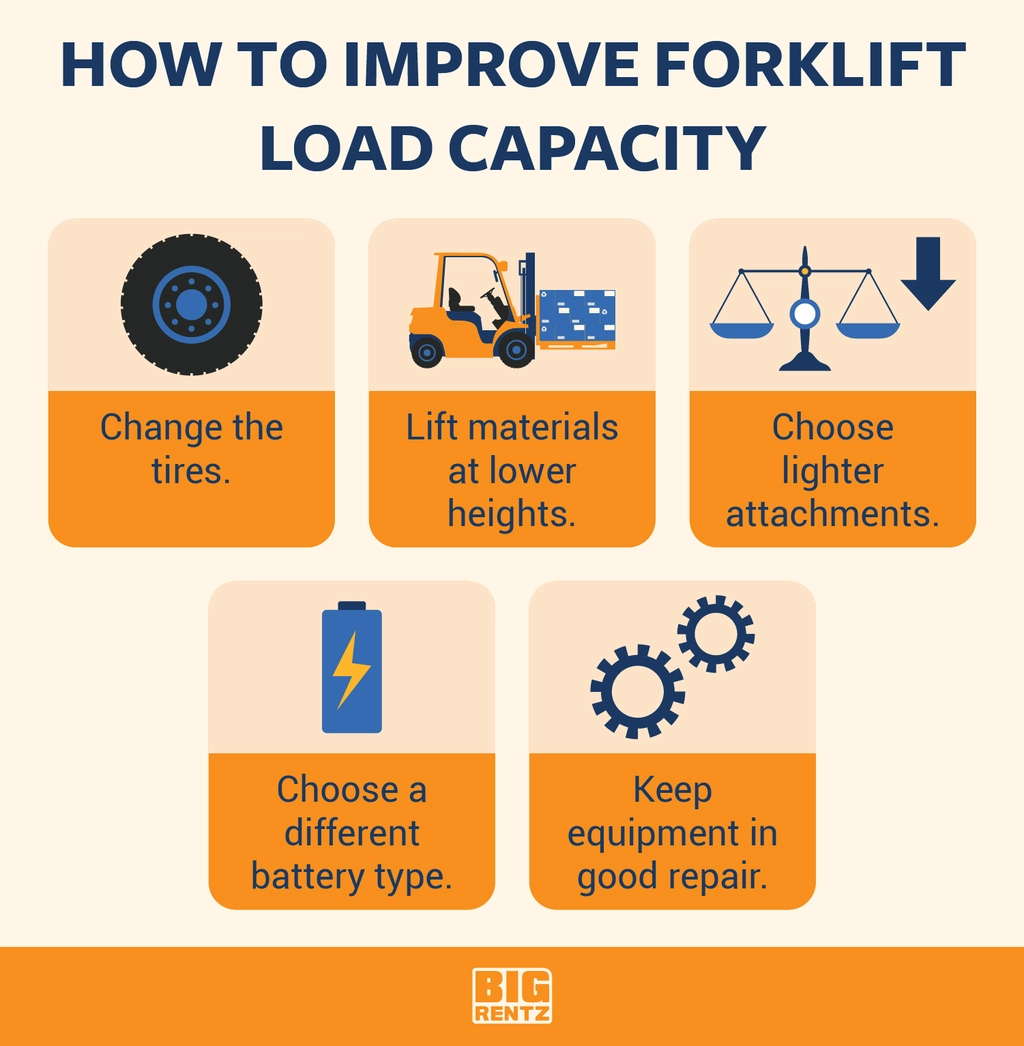

You can improve your forklift lifting capacity by maintaining the machine properly and making adjustments to your material and procedures.

- Change the tires: A dual-tire forklift can increase your lifting capacity. Choosing cushion tires over pneumatic tires can give you an advantage as well.

- Lift materials at lower heights: The lower your lift, the lower your center of gravity, which means you’ll have less risk of tipping.

- Choose lighter attachments: An attachment can reduce lift capacity by extending the load center forward and by adding weight to the load itself.

- Choose a different battery type: Batteries act along with a forklift counterweight to stabilize a load, so a heavier battery can reduce safety risks. Check your lift’s specifications to ensure you have a battery heavy enough to meet its requirements.

- Keep equipment in good repair: Make sure your machine is properly maintained and that its parts are all in good working order.

Calculating Load Moment

The load moment increases when the load center distance increases, just as a box feels heavier if you hold it with your arms extended than it does when resting at your waist. So when you think about the load moment, think about how the weight of your load gets distributed. Mathematically, the load moment equals the weight of the load multiplied by the distance of the load from the fulcrum, which is the pivot point. For most sit-down, counterbalanced forklifts, the front axle acts as the pivot point.

When deciding which forklift to rent, read the forklift’s data tag and calculate its load moment to ensure it gives you adequate load capacity for your job. If your lift calls for 3,000 pounds at a 24-inch load center, you could calculate your load moment by multiplying these numbers together to arrive at 72,000 inch-pounds. To keep the load moment within specifications with a greater load center, you need to reduce the weight of your load to keep the result at 72,000.

Why Forklift Weight Matters

Knowing the service weight of a machine can help forklift operators determine how much it will be able to carry. Once you know the kind of loads you will be handling on your project and how high you need to lift them, you can decide on the best forklift to rent.

The service weight also helps you determine whether you can operate a given lift safely by maintaining stability and proper weight distribution, while guarding against hazards such as falling loads or tipovers.

Consider the ways in which knowing forklift weight matters for your next job:

- Helps inform attachment use: Knowing the total weight of your forklift and its capacity can help you decide the weight and kinds of attachments you can use safely.

- Determines load capacity: If you know your forklift weight, you can decide how much you can carry and whether the lift you’re considering can perform the job you’re planning.

- Safer operation: You need a lift that’s heavy enough to do the job without overloading the forks or raising them higher than recommended to remove or place loads.

Conclusion

Whether you’re planning to operate a forklift outdoors or in a warehouse, knowing its weight is the first step in being able to determine whether it can do the job you’ve got planned. You need a lift heavy enough for material handling with the capacity to perform safely and efficiently.

BigRentz has a variety of forklifts for rent at different weights ranging from 5,000 to more than 100,000 pounds. Models are available with counterweight extensions, the capability of reaching higher load sites, and pneumatic or cushion tires.