Forklifts are used for lifting and transporting heavy loads. You can fit them with a variety of attachments to increase their functionality. For example, material handlers and movers can use attachments to transport everything from carpet rolls to propane tanks. This article will explain popular forklift attachments and their primary uses.

1. Carpet Poles

Carpet poles or rug poles extend out from the forklift, allowing the driver to insert them into a rolled carpet’s center core. Once secured, the carpet can be lifted from its current position and moved to a different location.

2. Cylinder Caddies

Cylinder caddies are steel attachments with spaces to accommodate several liquid propane tanks for transport. They allow you to move propane cylinders securely from one place to another. Safety chains keep the cylinders upright and in place while they’re being moved.

3. Fork Extensions

If you have a larger load than will fit on your standard fork, you can add extensions to increase your carrying ability. They come equipped with restraining straps to keep the load in place and guard against slipping.

4. Fork-Mounted Drum Handling Equipment

Drum attachments are equipped with arched clamps that can extend to grab plastic or steel drums. They come in several configurations, such as grabbers, lifters, and carriers. They’re available to fit drums of different capacities, including 30- and 55-gallon containers, and can carry 1,000 pounds or more.

5. Fork Positioners

Fork positioners allow you to move the forks without leaving your seat. Powered by hydraulics, they’re an efficient and effective alternative to repositioning your forks manually. This is especially useful when you have to handle pallets of different widths on a regular basis. This attachment can reduce pallet and product damage, and it can also improve safety by keeping the forklift operator inside the forklift truck.

6. Multiple Load Handlers

Multiple load handlers add extra forks to your forklift, allowing you to carry more pallets at once. You can expand your capacity to two or even three side-by-side sets of forks. This forklift attachment is often used in production, warehousing, shipping, and bottling/brewing tasks.

7. Masts

Forklifts have several types of mast options: single-stage, two-, three-, and four-stage, each allowing you to hoist material to greater heights. Mast extensions are lifting attachments that allow you to raise the materials higher without needing a forklift with a larger mast.

8. Paper Roll Clamp

Paper roll clamps are large, sturdy attachments that can secure and move large rolls of paper without damaging it. They can handle one to eight rolls at a time, of various sizes and weights.

9. Push-Pull Clamp

This hydraulic attachment extends forward and clamps around a load, squeezing it between a faceplate and gripper to transport it without the use of pallets. Materials are packed onto slip sheets instead.

10. Rollerforks

Rollerforks are specialized attachments that eliminate the need for pallets. Two layers of rollers are used. The lower layer moves forward while the upper layer moves backward, helping to secure the load. Rollerforks are often used with slip sheets, but may be used without them for certain load types.

11. Rotators

If you’ve ever enjoyed sipping a cup of coffee or tea, you’ll have a good idea of how a rotator attachment works. Rotators allow you to rotate the forklift’s forks to one side in a tipping motion. The advantage of rotators is they can be used to pour out the contents of bins. You can also tip containers to one side so you can reach in and retrieve something.

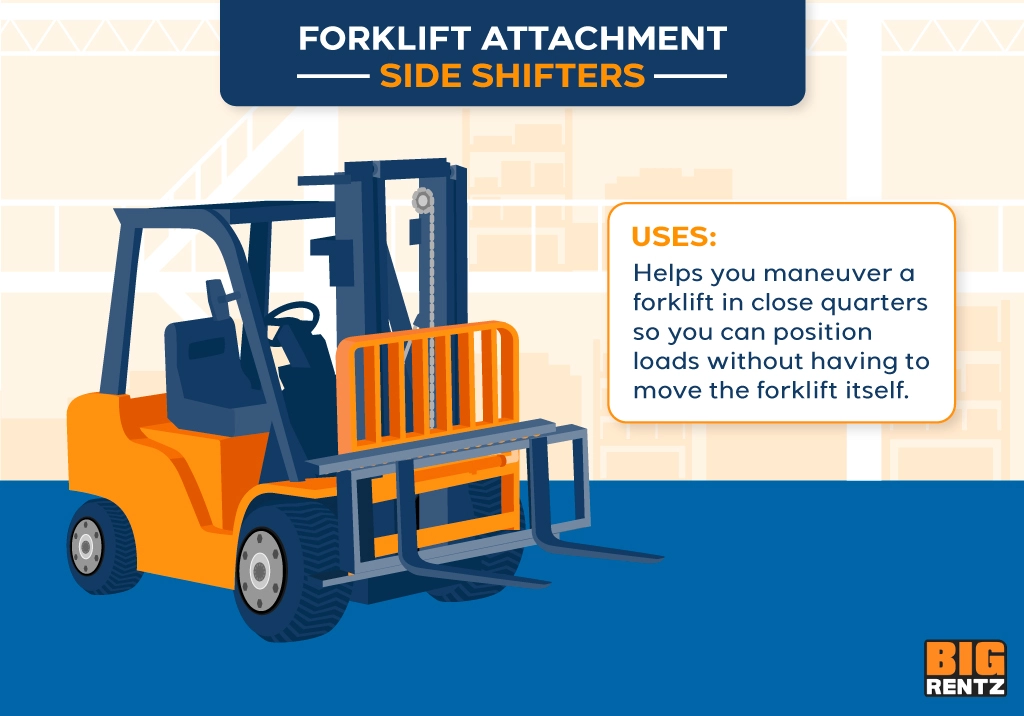

12. Side Shifters

This attachment allows you to move a load that’s being carried from side to side. A side shifter can help you maneuver a forklift in close quarters, so you can reposition loads to be stored without having to move the forklift itself.

Which Attachment Do I Need?

Knowing what kind of job you’ll be doing is the first step to deciding what kind of attachment you’ll need. You’ll want to take into account weight and height requirements, as well as the nature of the job site and what you’ll be moving. Safety is an important consideration as well.

Project Type

What you’re moving and the space you’re working with will determine which forklift attachments may be beneficial. Attachments such as carpet poles, paper roll clamps, and cylinder caddies are designed to move specific kinds of materials. If you’re operating in close quarters, you might want to consider a side shifter; if you want additional height or need more capacity, you can choose a mast extender, multiple load handler, or fork extension.

Load Weight

You’ll want to think about how much weight your forklift can handle and what you’ll be moving. Forklifts can roll over if they’re overloaded, so it’s important to maintain a low center of gravity and keep loads balanced and centered to avoid accidents.

Load Height

How high do you need to lift your load? That’s one important question to ask in determining what attachment you choose. But it’s also important not to extend your mast higher than your forklift can handle. Vehicle tip-overs account for 42% of forklift accidents, the largest single category.

Download our FREE forklift rental guide e-book today!

Conclusion

Attachments can make forklifts more versatile. When using a new attachment, make sure you know what safety precautions to take.

If you need a forklift for a short-term or one-time use, renting one is a good option that can save you money. Current prices at BigRentz range from $45 a day and $125 a week for a manual pallet jack, through about $150 a day or $350 a week for a warehouse forklift with pneumatic tires, to $420 a day or $1,100 a week for a 10,000-pound, 42- to 48-foot telehandler.