Generators are useful devices that provide electricity without needing access to the power grid. They can serve as a backup power source for worksites, homes and businesses, and they keep critical systems running when the power goes out. So, how do generators work?

Simply put, generators work by converting mechanical energy into electrical energy using an engine, alternator and an outside fuel source. Modern generators work on the principle of electromagnetic induction, a term coined by Michael Faraday when he discovered that a conductor moving in a magnetic field can create and direct electrical charges.

Understanding how generators work can help you identify problems, perform routine maintenance and choose the right generator to suit your specific needs. In this guide, we’ll go over the basic components of a generator and how they work, step-by-step.

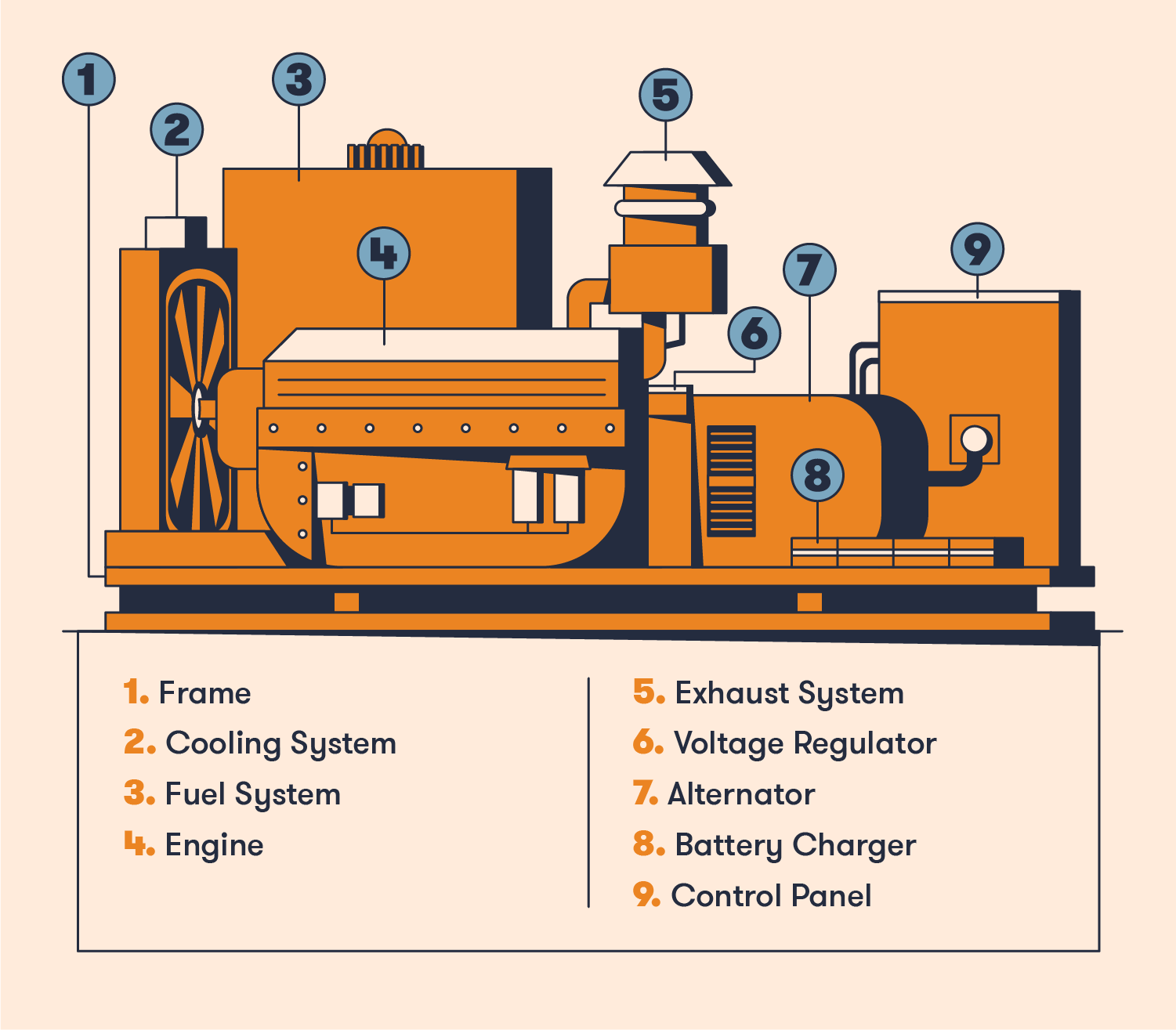

8 Basic Components of a Generator

Modern electric generators can vary in size and application, but their inner workings are generally the same across the board. The basic components of an electric generator include:

- Frame: The frame contains and supports the generator’s components. It allows humans to safely handle the generator and protects it from damage.

- Engine: The engine supplies the mechanical energy that is converted into electrical output. The engine’s size determines the maximum power output, and it can run on a variety of fuel types.

- Alternator: The alternator contains additional components that work together to produce the electrical output. These include a stator and rotor, which are responsible for creating a rotating magnetic field and producing an alternating current (AC) output.

- Fuel System: Generators come with an attached or external fuel tank that supplies the engine with fuel. The fuel tank is connected via supply and return pipes and commonly contains gasoline or diesel fuel.

- Exhaust System: Diesel and gasoline engines emit exhaust containing toxic chemicals. The exhaust system safely manages and disposes of these gases through a pipe made of iron or steel.

- Voltage Regulator: This component is responsible for regulating the generator’s voltage output. The voltage regulator kick-starts the cycle of converting AC current to AC voltage when the generator falls below its maximum operating level, and it settles into a state of equilibrium once the generator reaches its operating capacity.

- Battery Charger: Generators rely on a battery to start up. The battery charger is responsible for keeping the battery charged by providing a float voltage of exactly 2.33 volts per cell.

- Control Panel: The control panel is located on the outside of the generator and contains multiple gauges and switches. Features can vary by generator, but the control panel typically includes a starter, engine control gauges and a frequency switch.

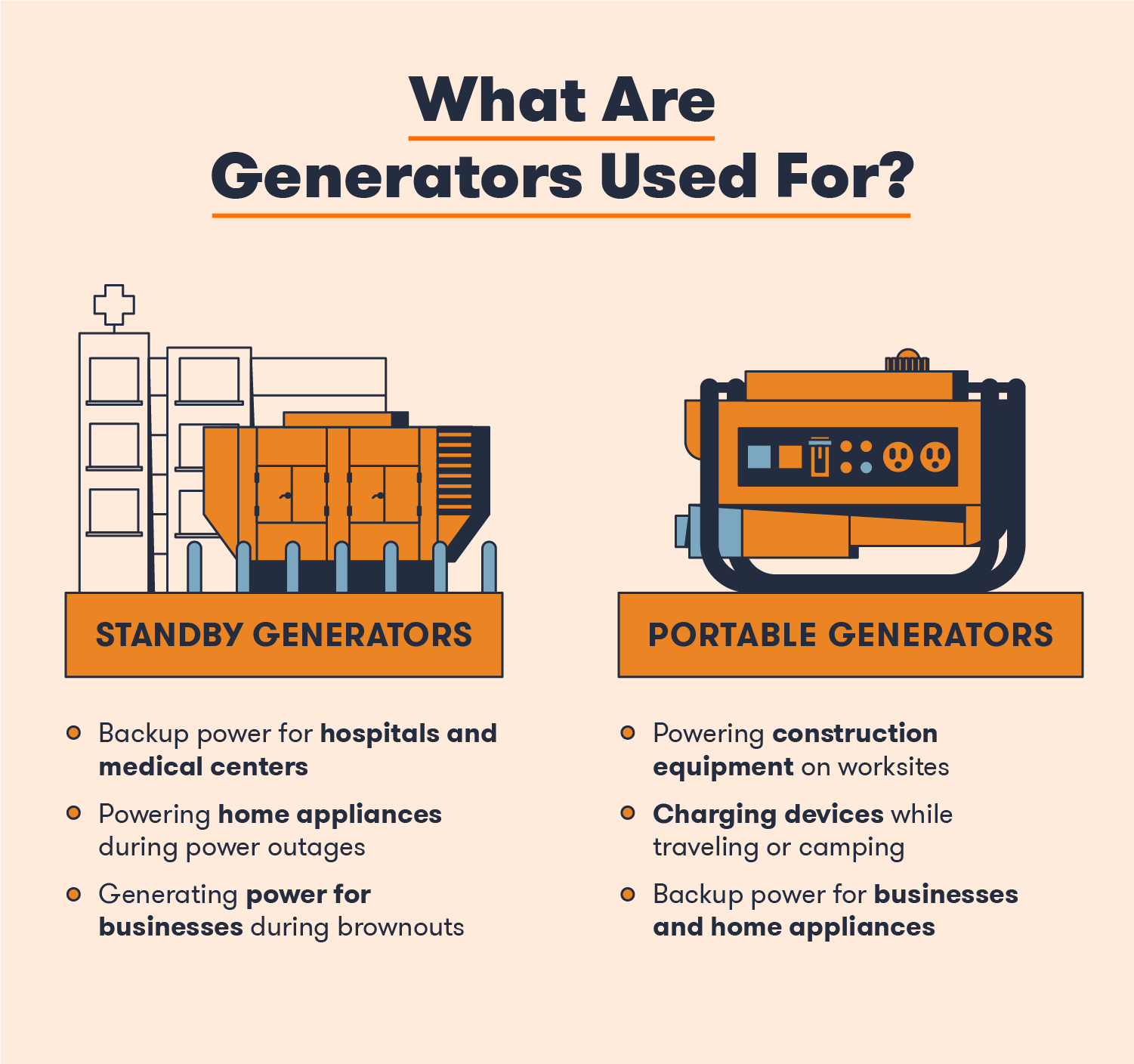

What Is an Electric Generator Used For?

Electric generators are made for both personal and commercial use. They are most commonly used as a backup power source in the case of a brownout or power outage, but they can also function as a primary power source for buildings or construction sites off the power grid.

Standby generators are the type most commonly used for backup power in homes, offices and medical facilities. These generators connect to a building’s electrical system and start up automatically when the power goes out. They are permanent fixtures once installed, and their fuel tanks are typically large enough to provide power for several days before needing a refill.

Portable generators are smaller and easier to move than standby models, making them perfect for powering appliances, travel equipment and construction equipment on worksites. They come in multiple sizes and wattage options for different applications. Smaller portable generators may only be able to power one or two tools at a time, while the largest models can power entire buildings.

How Generators Produce Electricity: A Step-by-Step Breakdown

Generators actually don’t produce electricity. Rather, they convert mechanical energy into electrical energy. The process can be broken down into the following steps:

Step 1: The engine uses gasoline, diesel fuel, propane, natural gas or a renewable energy source to create mechanical energy.

Step 2: The alternator uses the mechanical energy produced by the engine to push electric charges present in the generator’s wiring through an electrical circuit.

Step 3: The movement creates motion between magnetic and electric fields. During this process, the rotor produces a moving magnetic field around the stator, which contains stationary electrical conductors.

Step 4: The rotor converts the DC current to an output of AC voltage.

Step 5: The generator supplies this electric current to appliances, tools or a building’s electrical system.

Download our FREE generator rental guide e-book today!

Advantages of Modern Generators

Generators have been around for decades, but technology is constantly evolving to make them more efficient and reliable. Modern generators now come with a variety of new features and capabilities.

Portability

Advances in technology often come with the benefit of more compact parts, and generators are no exception. Smaller, more efficient batteries and engines allow portable generators to handle longer run times and higher power outputs. Even some industrial generators are towable and can be transported from one place to another.

Small Environmental Impact

Generators fueled by renewable energy sources are quickly increasing in popularity. Some people are choosing to ditch gas- and diesel-powered generators for more eco-friendly models powered by solar, wind turbines or water turbines. Natural gas is also a popular power option for home and business owners seeking to reduce their carbon footprint.

Substantial Power Output

While not everyone needs a high power output, businesses and large construction sites typically require more power from their generators. Fortunately, modern generators can have a capacity of 300 kilowatts or higher. The largest, most powerful generators still typically require diesel fuel to function, but that is likely to change as technology advances.

Noise Reduction Features

The larger the generator, the more noise it tends to produce. To cut down on noise pollution, manufacturers have started including high-quality noise reduction features in their products. If your generator doesn’t come with this feature, you can purchase a separate generator silencer or muffler and attach it yourself.

Having a generator on hand can keep operations running as usual when the power goes down. Whether you are renting a generator for your next construction project or buying one for your business, knowing how generators work can inform your next purchase decision and make maintenance a breeze.