Pallet stacking involves stacking boxes of different sizes and weights on pallets to prepare goods for storage or transport. This can be done manually or with the help of material handling equipment like forklifts or pallet jacks.

While pallet stacking may sound easy, it takes strategy to ensure the weight is evenly distributed and the load is stable. That’s why it’s essential to understand how to safely stack pallets and which patterns are optimal for a balanced load. Safe and efficient pallet stacking ensures goods get where they need to go without getting damaged or causing injury to your workers.

This guide aims to help you navigate pallet stacking and how to do it correctly to avoid injuries, prevent loss, and maximize efficiency.

Explore All Warehouse Forklifts

Steps for Safely Stacking Pallets

Stacking pallets can be dangerous if it isn’t done safely. Potential safety hazards like falling materials and collapsing loads can cause serious injury or even death.

While pallet patterns are important to load integrity, they shouldn’t be your only consideration. It’s important to use other stabilizers, like slip sheets, corner boards, straps, or stretch wrap, to maximize integrity.

Here are the steps you need to take for proper pallet stacking.

1. Examine the Load and Its Weight

First, evaluate the items you need to stack and their weights. Make sure you assess the pallets themselves as well as their condition and load capacity. Damaged pallets aren’t safe to use.

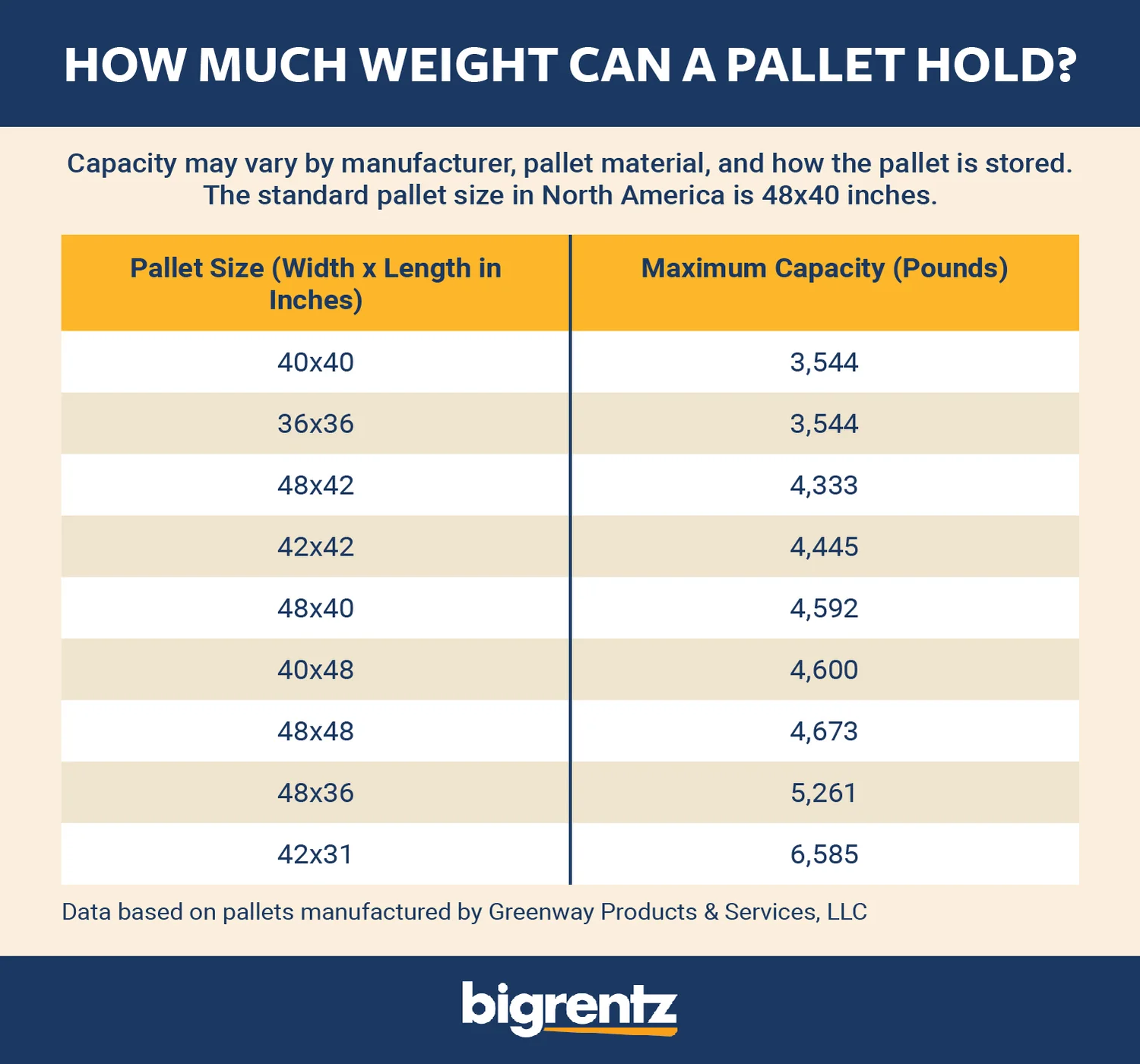

The heaviest weight your pallets can safely hold and move is based on the type of pallet you’re using, the type and material of the load you’re stacking, and the equipment you’re using to move the pallets. Standard 48×40 pallets must have a minimum load capacity of 2,500 lb, but can often hold up to 4,600 lb. Load capacity varies by pallet size and your pallet storage method.

Just as you don’t want to exceed the weight limit your pallet can hold, you should also be careful about how high you make your stack. Be sure your stacking height isn’t so high that it blocks your vision or causes boxes to become unstable and tumble off.

2. Determine the Ideal Stacking Pattern

Based on the boxes you have, their sizes, and weights, stack them according to the safest palletizing configuration – more on that below. The key to a safe pallet is partly using the appropriate pattern for the load you’re dealing with.

If you have various sizes and shapes of boxes, you may consider an interlocking method. If you have boxes of the same size and shape, you might consider the blocking technique.

No matter what materials you’re dealing with, don’t stack pallets in a pyramid shape, since this puts too much strain on the center of the pallet. Also, avoid carton overhang, arranging boxes as close to the edge of the pallet as possible.

3. Ensure Weights Are Distributed Properly

Once you’ve figured out the stacking pattern, you should determine where to place each box for proper balance and weight distribution to avoid injury or accidents. Heavier loads should be placed first, at the bottom of the stack, to create a stable base, followed by lighter ones all the way to the top to prevent the heavier materials from damaging the lighter ones.

4. Secure the Boxes with Straps, Tape, or Wrap

Once you’ve configured your load, secure the boxes with straps where needed and add shrink wrap on top of that. Wrapping the entire unit, load, and pallet, with multiple layers of plastic wrap binds the items to the pallet. This helps prevent the boxes from shifting, falling, or otherwise causing accidents and injuries during transportation.

For additional safety, you can add foam or cardboard corner protectors to your loaded pallets.

5. Configure a Clear Travel Path

Once you’ve secured the pallets, you’re ready to transport them to their final destination. Before you do that, make sure the path you need to take is clear of any obstructions. This may involve putting signs up to not block certain areas and communicating with your team and others in the area before you begin your transport and as you travel along the path.

What Are the Various Pallet Stacking Patterns?

Whether you’re palletizing with machinery or manually stacking pallets, it’s important to follow the right stacking pattern for your load. The two main methods of stacking boxes are:

- Column stacking: This method involves piling boxes vertically so boxes are stacked symmetrically, box on box. Large boxes and lighter boxes work well for column stacking. You can add sheets between each layer and use shrink wrap to help increase stability. This method isn’t ideal if boxes are stacked too high, because they can easily fall off.

- Interlock stacking: This method involves layering boxes to fit together as efficiently as possible. Boxes that vary in size and shape are best to interlock because it helps ensure their weight is distributed evenly. However, you can’t typically stack as many boxes using this pattern because you have to be careful not to upset the weight distribution.

Within these two methods are various options for stacking patterns. Let’s take a look at some of the most common ones.

Column Stacking Examples

Here are some of the most common patterns for column stacking.

1. Block

The block pattern involves stacking boxes in a block-like formation. It works well for goods with uniform dimensions, and provides great stability for products that can handle weight distribution.

2. Split Block

The split block pattern is a modified version of the block pattern, it splits the columns by size. For example, narrower boxes can be stacked in the center column, flanked by wider boxes on the side columns. This technique can be used for products of different sizes because of how it helps distribute weight.

Interlocking Examples

Here are some of the most common interlocking patterns.

1. Split Row

The split row pattern involves staggering boxes in adjacent rows to create a stable arrangement. Boxes are interlocked by turning each layer by 90 degrees compared to the one below it, which helps keep them in place. This method helps stabilize boxes of various sizes and prevent overhanging on pallet edges.

2. Row

In the row pattern, boxes are placed side-by-side in an interlocking arrangement. It works best for long and narrow boxes or those that need to be accessed one at a time. This technique may help improve the visibility of the boxes on your pallet for labels or barcodes if you need to identify them quickly.

3. Brick

This pattern looks as you might imagine from its name—it alternates the alignment of boxes in each layer, like bricks. It’s another variation on the interlocking method since boxes are stacked like a brick wall. This technique works best for enhancing stability for boxes that require even weight distribution, especially for lighter boxes, so there isn’t as much stress on the bottom layer.

4. Pinwheel

The pinwheel pattern involves placing boxes diagonally on the pallet with some gaps in between, creating a pinwheel shape. The gaps allow for some movement and shifting and also accommodate irregularly shaped boxes and different sizes. You can use this pattern for boxes that tend to—or need to—shift around.

5. Hybrid Pinwheel

A variation on the pinwheel, this pattern is similar to the brick pattern in how the boxes are stacked. It’s a great option for various box sizes or mixed loads. Just ensure you consider how the different sizes can impact the overall weight distribution and balance in your stack.

What Is OSHA’s Guidance for Safe Pallet Stacking?

OSHA offers comprehensive guidance on safe pallet stacking. Here are some best practices to keep in mind:

- Avoid mixing pallet sizes in your stack. A pallet of an odd size at a key point in your stack, such as near the bottom, can compromise the stability of your entire stack.

- Avoid stacking pallets on their sides, which can also cause instability.

- Stabilizers like pallet stacking frames and pallet racks should be used to support load integrity.

- Don’t reuse damaged pallets—they aren’t stable. Also, issues like splintered ends or protruding nails from damage can cause injury to your workers.

- Make sure your stacks are at a safe height. Don’t allow stacks to reach too close to the ceiling, especially if they’re close to your sprinkler system. Be sure to keep at least 18 inches of vertical clearance between your stack and the sprinklers.

Also, while stacking empty pallets can save floor space and reduce tripping and collision hazards, make sure they’re stacked carefully and within a safe height so you aren’t creating additional hazards.

Why Is Pallet Stacking Important To Do the Right Way?

Proper pallet stacking is crucial to occupational safety for workers and teams all along the supply chain, especially for those working as shippers or in warehouses. Stacking pallets the right way prevents injuries and accidents when loading, transporting, or unloading.

Pallet patterns also contribute to sustainability. They influence cube utilization, which impacts the number of individual shipments or conveyances your teams have to make, affecting fuel and emissions. They’re also important for using warehouse space efficiently, and preventing damage to your products.

What’s the Best Equipment for Transporting Pallets?

Forklifts, telehandlers, and pallet jacks are perfect for transporting pallets to, from, and within warehouses. Here’s an overview of these material handling machines:

- Forklifts: A type of heavy equipment, forklifts are optimized to carry, lift, and move heavy palletized materials.

- Telehandlers: Telehandlers are high-reach forklifts, making them ideal for hard to reach places that might need to be accessed while lifting and unloading loads in warehouses.

- Pallet jacks: The smallest machines of the three, pallet jacks can move palletized loads and are ideal for navigating narrow passages.

Explore All Warehouse Forklifts

Ready to Stack Pallets?

Now that you know how you properly stack pallets, you’re ready to stack any pallets coming your way! Remember, proper stacking technique not only promotes workplace safety, but it also helps productivity by maximizing warehouse space and making loading and unloading more efficient.

If you need some help with your material handling, you can always rent material handling equipment from BigRentz.