A man lift is a specialized aerial work platform (AWP) that is designed to safely lift a worker and their equipment on indoor and outdoor worksites. They’re differentiated from other aerial lifts like boom lifts, based on size, appearance and use.

Known in the industry by several names, man lifts are often referred to as man lifts, personal lifts and personnel lifts. There are three types of manlifts: self-propelled, push-around and belt-driven. All vary in size and specialization.

Understanding the different types of manlifts can be a bit confusing. They all have similar features, but are used for different jobs.

In this post, we’ll examine the different types of manlifts, the features they offer and when best to use them. Here are the three main types of manlifts:

1. Self-Propelled Manlifts

The self-propelled manlift is the smallest of the group. The compact lift can raise one person and a set of tools 15-to-20-feet in the air. It’s size makes it easy to maneuver through doorways.

Self-propelled manlifts reach ladder heights, but have more foundational stability. The collapsable frame is ideal for working on small-scale indoor projects that need a moderate height increase.

Explore All Drivable Man Lifts

2. Push-Around Manlifts

Push-type man lifts are slightly larger than the self-propelled models. They can reach heights of 15-to-50-feet, enabling a single worker and their tools to fit into tight spots like between rafters or around alongside an HVAC unit. Even photographers can use the push-around manlift to get a bird’s-eye view above crowds.

The collapsible frame and hydraulic wheels make it easy for one or two people to maneuver the lift through doorways and down corridors. Due to the light frame (200-to-400-pound weight capacity) and vertical reach, push-around manlifts have retractable outrigger legs that stabilize the base and prevent tipping.

3. Atrium (Belt) Manlifts

Atrium manlifts, also known as compact crawler lifts, are the largest in the group. The heavy-duty lift is best for outdoor construction sites. The retractable legs and tank-like drive tracks, enable the atrium to securely sit on unstable surfaces like dirt, sand and mud.

The extended neck can reach heights of over 34-feet and rotate 360 degrees. The jib joint allows for maneuvering around obstructions like, trees and power lines. Some atrium manlift models are battery-powered, while others run on gasoline and diesel fuel.

What Is a Jib on a Manlift?

A jib is a term that describes an extension of the arm that contains an extra joint for greater range of motion. Operators can move up and down, left and right with ease. The jib feature can also be found on the atrium lift and boom lift.

In the next section, we’ll look at the parts that make up a manlift and how it operates.

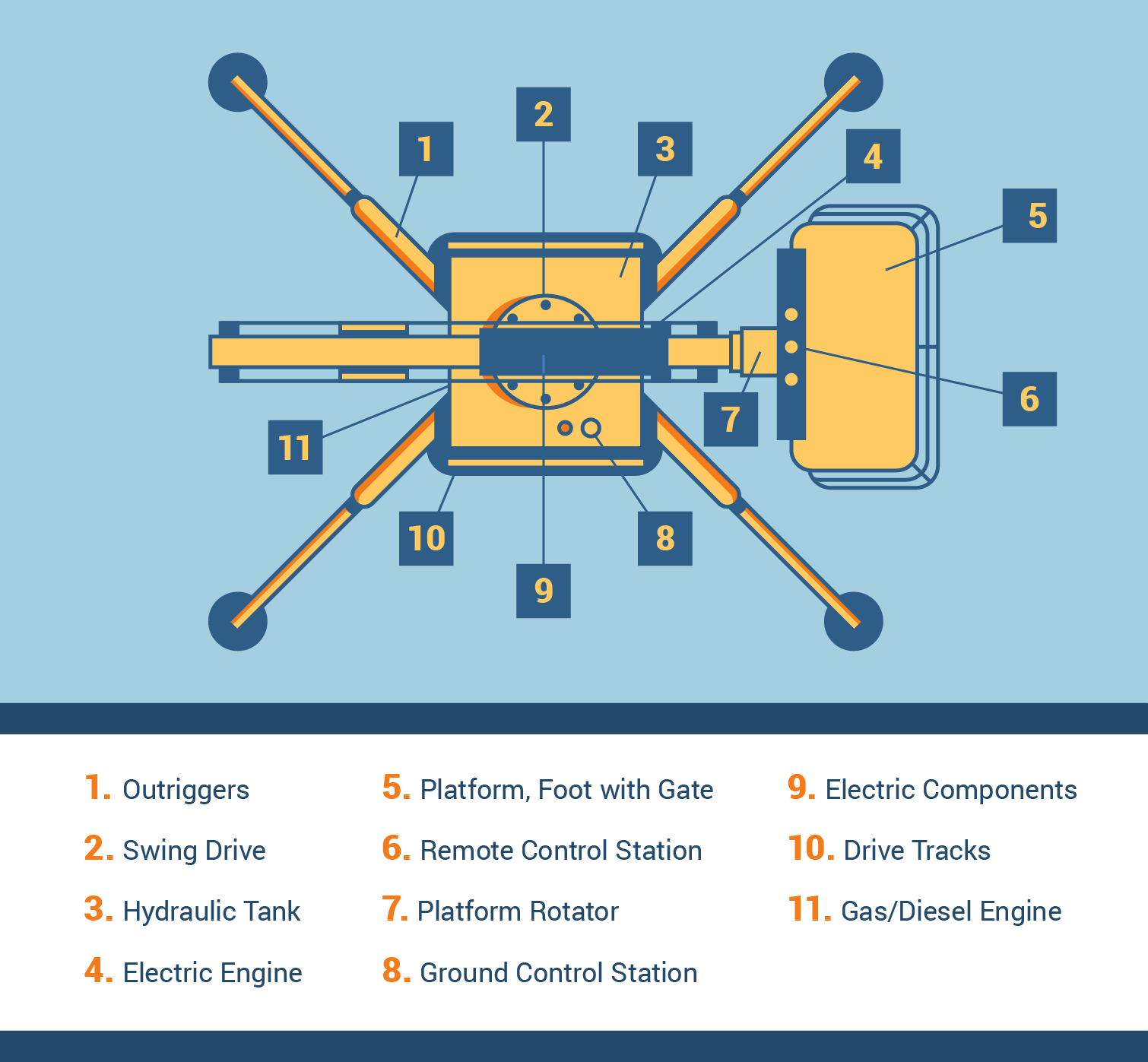

What are the Parts of a Manlift?

Manlifts contain many moving parts that help get jobs done. The retractable outrigger legs and drive tracks stabilize the foundation on any terrain. The platform control station operates the vertical extension and rotation movements. These functions keep the manlift running smooth and safe, for operators and those within proximity.

Let’s take a look at the different parts that make up a manlift. For this example, we’ll be using a JLG Compact Crawler® atrium manlift.

Since a lot of the manlift parts cross over with other equipment, let’s take a look at how different it is from another popular piece of machinery: the boom lift.

How Is a Manlift Different From a Boom Lift?

Boom lifts are a distant cousin to the manlift. Both enable operators to perform tasks in aerial workspaces. However, boom lifts have several different features than traditional manlifts.

Boom lifts can attach to work trucks and other vehicles to lift materials overhead. The jib (arm extension) can be telescopic or articulating, providing a greater range of motion than manlifts for working at difficult angles. On many of the boom lift models, work platforms tend to be larger than manlifts.

In short, a boom lift is a manlift, but a manlift is not necessarily a boom lift. Both are part of the AWP family but aren’t classified in the same category. Similar to the variation of manlifts, there are a variety of boom lifts for different construction needs.

How Much Does It Cost to Rent a Manlift?

The cost of renting a manlift can vary depending on the number of hours and days, weeks, or months needed. Manlift rentals can range from $100 to 200 per day, $200 to $900 per week, or $500 to $2,000 monthly. This is not an all-inclusive list but an estimate of what to expect.

When renting construction equipment, it’s important to consider the size of the project, the type of lift needed and the length of use. Be sure to include fuel costs into your budget. Indoor lifts like a self-propelled manlift can operate using an electrical socket. Outdoor manlifts like an atrium can run on batteries but also operate on gasoline.

This may seem like a lot to deal with, but buying an aerial lift is more expensive. The manlift will need a location for long-term storage and routine patience and check-ups. Owning heavy equipment also requires meeting national and federal regulations, like the American Society of Safety Professionals’ (ASSP) ANSI/SAIA A92.6 – 2006 (R2014) for aerial work platforms.

If you don’t have the upfront capital to buy a manliftt, renting could be the best option. The final step is to understand what to look for when choosing a manlift.

How to Choose a Manlift

When choosing a manlift, it’s important to have an understanding of the type of project, worksite and height needed to complete a job. These are a few of the main questions to ask that can save you a lot of time and money in the process.

Is your project indoors or outdoors? – Smaller models such as self-prop manlifts only operate indoors, while larger models atrium manlifts work outside.

How high does it need to reach?

Identify the highest point in your worksite and add six feet for an operator overhead clearance. Make sure to practice the three points of contact rule when getting on or off a manlift to ensure safety and stability at different heights.

Will you need a power source?

Indoor manlifts models can operate using an electrical socket. Outdoor lifts can run on batteries, but also use gas and diesel fuel.

Are there any worksite obstacles?

Take note of the environment and potential obstacles, like tight spaces or unstable terrain, to stay safe when operating a manlift. Smaller manlifts can raise an operator between tight spaces and crevices. If a worksite surface is unstable, outriggers posts and drive tracks can provide extra foundational support.

Single man lifts are an essential tool to many jobs. From painting a ceiling or washing office windows on the second story, the manlift can help do the job.